Art, Armor, and Airbags: Spider Silk As A Miracle Material

That spider is sitting on a goldmine! (Photo: Takuma Kimura on Flickr)

At Will Knight’s Spider Web Farm in Williamstown, Vermont, the farmers don’t rely on Charlotte’s Web-style barnyard serendipity to make silk—the arachnid webs are carefully cultivated on frames. Once a web is spun, it is spray painted white to make it stand out, preserving the work with a layer of lacquer and a wooden frame. The spiders (orb-weaver spiders to be exact) are just creating a home, but to Knight, they are spinning fractal works of art, each as unique as a snowflake. Both see spider silk in different ways, but one thing is clear. It’s a miraculous material.

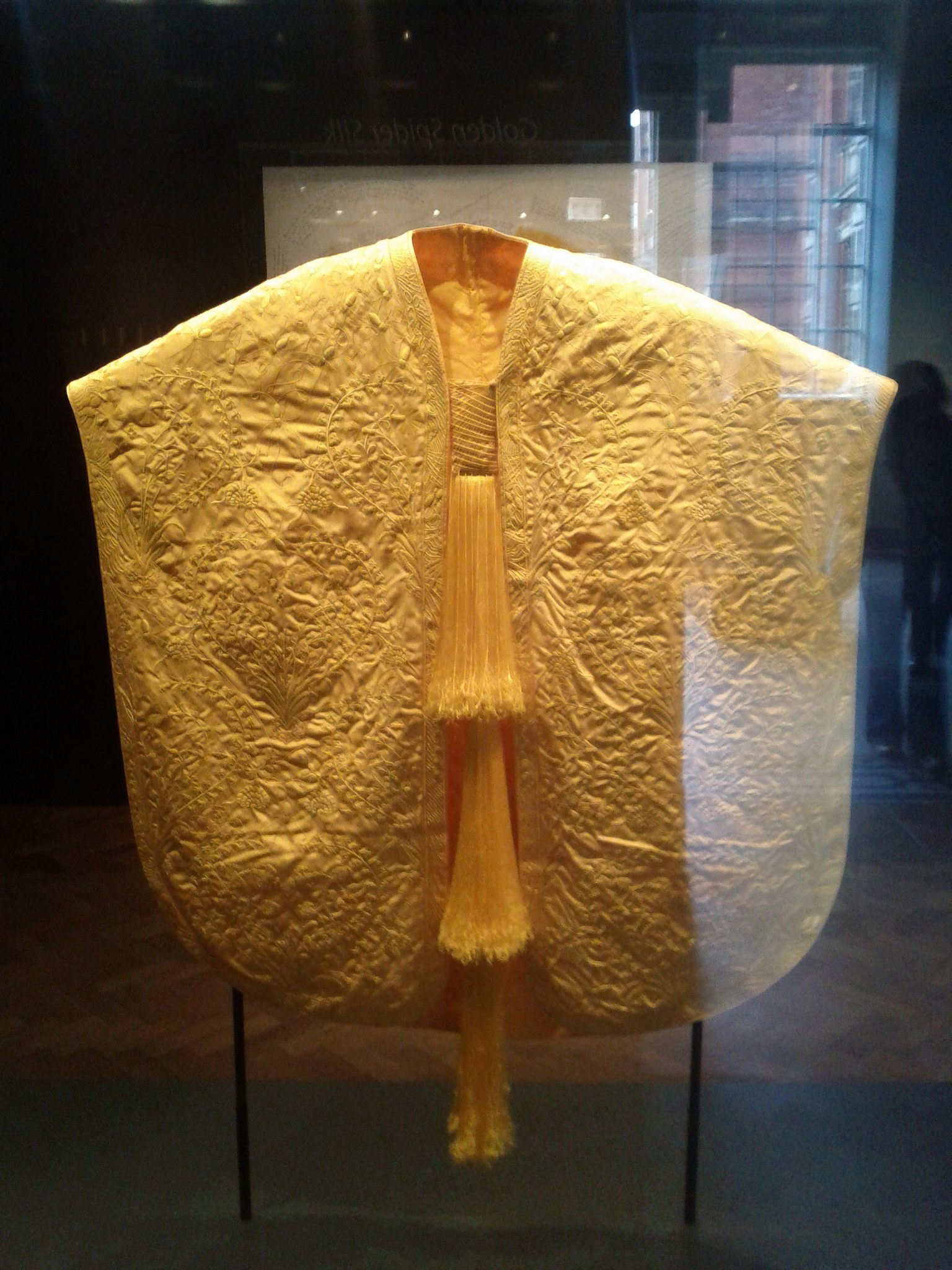

Resilient and almost ephemerally light, spider silk is one substance that humans have never been able to replicate in any quantity worth noting. Knight is not the only one who saw the artistic potential in spider silk. In fact, the single largest piece of spider silk cloth ever created was made as a piece of art. Finished in 2009, a large golden cape was created that spanned 11 feet by 4 feet of intricately embroidered silk cloth. The project was spearheaded by artists Simon Peers and Nicholas Godley, who oversaw a team of over 80 workers who toiled for four years to create the garment. Dozens of people would head out into the Madagascar wilderness to collect golden orb spiders, which would then be milked for their silk. This silk was then woven into thread for the cape. In the end, it was estimated that over a million spiders were used in the creation of the golden throw.

Yes, that is pure spider silk, in its natural color. (Photo: Ian Irving on Flickr)

While these uses focus on the aesthetic beauty of the material, its durability is also a thing of legend (and science). There is an oft-repeated adage that says spider silk is stronger that steel, and in some ways this is true. While a strand of spider silk is not necessarily harder to break than a strand of steel the same size would be, spider silk has a remarkable amount of elasticity that allows it to bend and absorb energy in ways that steel, and really, most other popular materials cannot match. This property has made spider silk a popular candidate for the future of armor. Were scientists able to harvest enough silk to create a layered piece of body armor, it is theorized that it would be as much as three times stronger than kevlar, as well as lighter and more flexible.

Silk’s amazing ability to absorb shock energy has other potential applications such as in airbags and replacement joints.

The strength and elasticity of spider silk is not its only sought after feature. Spider webs are also naturally adhesive, as anyone who has ever gotten themselves tangled in one can attest to. This natural glue is unique in that it needs to be wet to work properly, which is the exact opposite of most synthetic adhesives. This natural stickiness could have uses ranging from waterproof bandages to ship repair.

Ship glue? (Photo: Vincent Lock on Flickr)

So, why aren’t we all driving silk cars and diving into battle wearing spider-armor? It’s simply because we are just not as skilled at making spider silk as spiders are. We are able to harvest spider silk in small quantities, and in fact, already have been for thousands of years. The ancient Greeks are said to have made bandages out of the stuff, and Native Australian fishermen have been observed using silk for fishing line. Strands of the silk were even used in telescopes and gun sights up until World War II. Unfortunately, even in the modern day, obtaining the silk has required farming the silk from the spider is a laborious and delicate process that does not produce enough for large-scale production (see the four-year cape above).

Many materials researchers and companies have endeavored to produce silk without the spider, but no matter science’s best efforts, we have yet to perfectly recreate what arachnids spin out so naturally. Everything from synthetic materials to injecting spider-genetics has been attempted without complete success. Some scientists in Utah have even gone so far as to splice goats with spider DNA, that they might produce silk in their milk. Truly the mad quest for silk will be our doom.

Despite the heated quest to find a way to literally make the most out of spider silk, Will Knight is content to just let them do their thing, allowing the spiders to mold their super-strong, material gold into beautiful shapes. The framed webs might not stop a bullet, or revolutionize materials science, but he sees how amazing the silken constructions are all by themselves.

Knight’s creations. (Photo: Michelle Enemark on Atlas Obscura)

Follow us on Twitter to get the latest on the world's hidden wonders.

Like us on Facebook to get the latest on the world's hidden wonders.

Follow us on Twitter Like us on Facebook