Strong, ME: The Rise and Fall of the Toothpick Capital Of The World

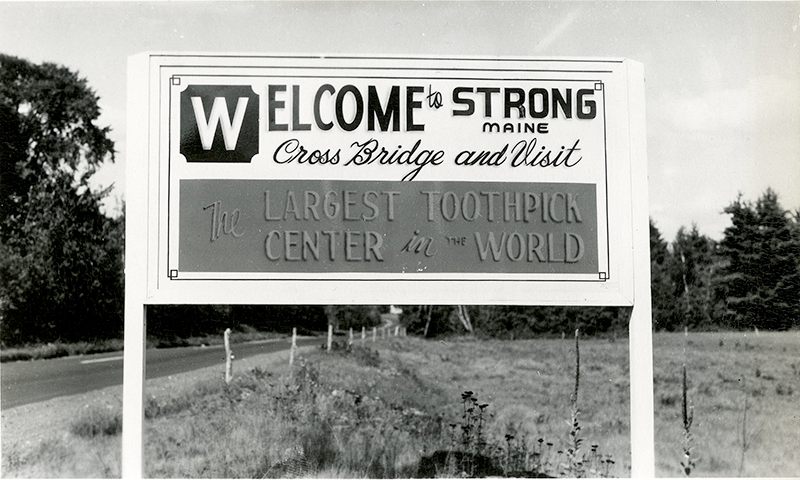

A sign for Strong, Maine, c. 1950s “The Largest Toothpick Center in the World”. (Photo: Collections of Strong Historical Society/ Courtesy vintagemaineimages.com)

Imagine you’re at a restaurant, a steakhouse perhaps, and at the end of your meal you notice a gobbet of flesh caught between bicuspid and molar. You probe it with your tongue, make darting forays into its enamel stronghold, but it just won’t budge.

Fortunately millennia of evolution and innovation have created the perfect tool to rid your mouth of this gristly intruder, and, up until just a few years ago, that tool would more likely than not have been made in the town of Strong, Maine, the Toothpick Capital of the World.

At one point, 95 percent of all wooden toothpicks manufactured in America were made in Strong and its environs. In the aftermath of WWII— Strong’s golden age—over 75 billion toothpicks were being made there a year. Not bad for a town of little over 1,000 people. But why did toothpicks become such a big business and how did a tiny town in rural Maine become a global toothpicking powerhouse?

To answer these questions you have to travel back 150 million years to the dawn of time.

Roman personal utensils from the Hoxne Hoard, which include an ibis toothpick (left). (Photo: Fae/WikiCommons CC BY-SA 3.0)

Roman personal utensils from the Hoxne Hoard, which include an ibis toothpick (left). (Photo: Fae/WikiCommons CC BY-SA 3.0)

Before man there was toothpick. Anthropologists have uncovered Neanderthal teeth with the unmistakable markings on them of toothpick use—it is perhaps humankind’s oldest habit. For millennia the toothpick has kept people company as their diet has changed from woolly mammoth to quarter pounder with cheese.

However, its form has differed immensely. Neanderthal toothpicks, probably made of out of stiff grass stalks, were soon superseded by toothpicks made of bone and slate. So necessary was the toothpick that the wealthy soon had ornate toothpicks made for them, carved from ivory or worked from silver into the shape of long-legged ibises or mermaids. They became status symbols and occasionally played central parts in skullduggery: Agathocles, a tyrant of Syracuse in the third century BC, was murdered when his enemy soaked his toothpick in poison. No matter where a civilization is based or what its level of sophistication, toothpicks have been ever present and can rightly be called one of the common denominators of this species.

While nearly anyone with opposable digits can craft a toothpick out of a twig or thorn, over the centuries small centers of toothpick manufacturing have sprung up. As Henry Petroski writes in his indispensable book on toothpicking, the earliest organized manufacturers of toothpicks were the nuns of the Mondego River valley in Portugal, who in the 16th Century made toothpicks to sell alongside the sticky confections that were their main source of income.

These toothpicks, made of orangewood, found their way to the Portuguese colony of Brazil where natives started copying them, and it was here in the middle of the 19th century that a Bostonian named Charles Forster had his first fateful encounter with them.

A detail from Paolo Veronese’s 1562 painting “The Wedding At Cana”, with a woman using a toothpick. (Photo: Public Domain/WikiCommons)

A detail from Paolo Veronese’s 1562 painting “The Wedding At Cana”, with a woman using a toothpick. (Photo: Public Domain/WikiCommons)

Forster was a great American entrepreneur. As he picked away at his teeth in the Brazilian heat with one of the locally made toothpicks, he saw a diastematic gap in the toothpick market. Somewhere between these Brazilian toothpick whittlers and the toothpick artisans of the regally wealthy lay a rich, untapped market. Some men dream of discovering strange new lands, others dream of worldwide fame, Forster dreamed of a machine-made wooden toothpick, a toothpick that would be of consistent shape and quality and available to princes and paupers alike.

In short he sought a toothpick for the modern world. There was only one problem. How was he to construct such a machine?

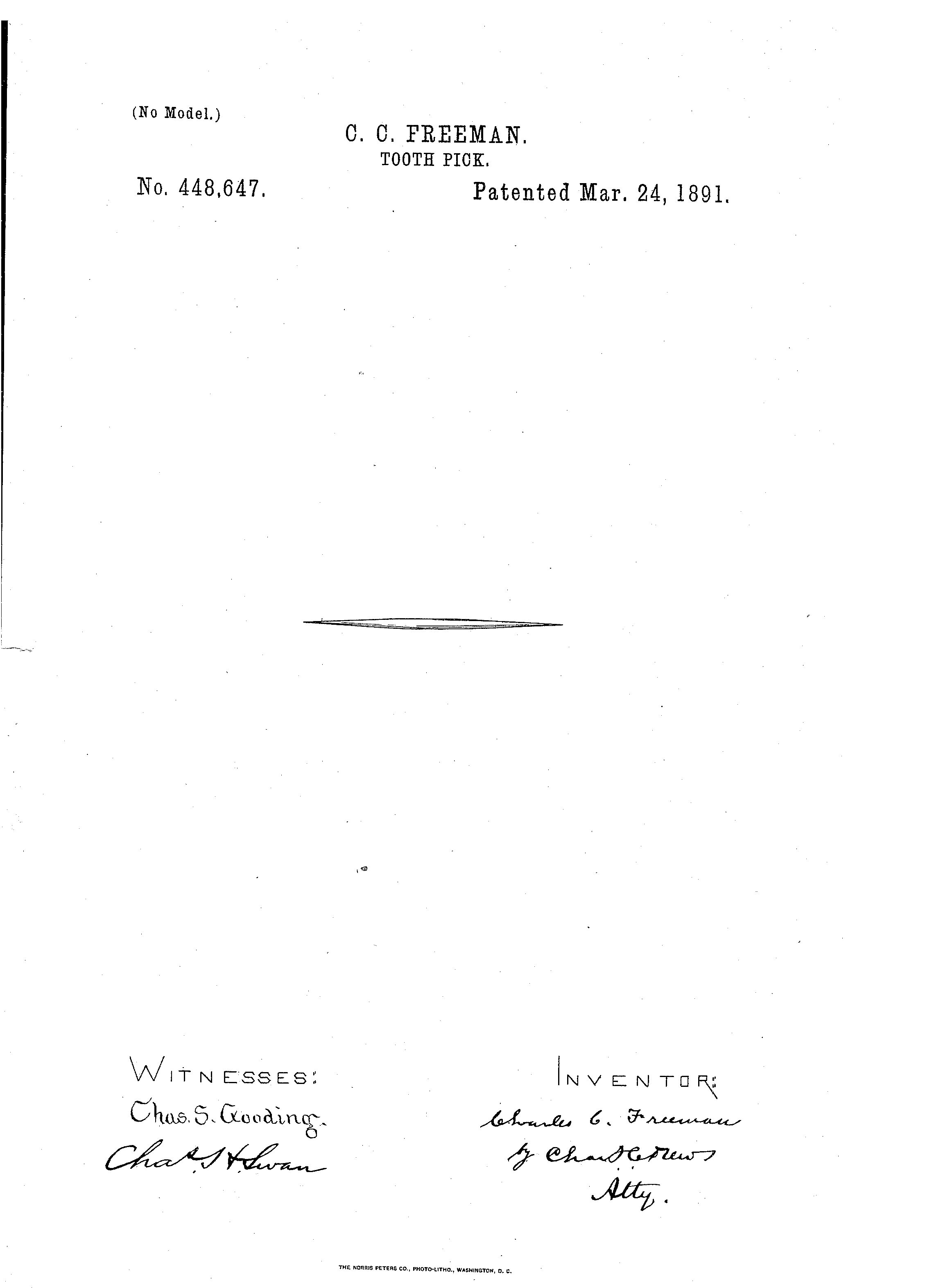

For help, Forster turned to the obscure world of shoe pegging. At that time most shoes had their soles attached to their uppers with wooden pegs rather than with stitching or glue. It was such a labor-intensive job—the pegs were driven in by hand—that fortunes were made by inventors who could automatize the process. These shoe pegging machines could peel logs into narrow strips of veneer from which uniform pegs could be stamped out. Converting one of these machines to his uses, Forster began testing out various different woods. In concert with the shoe pegging mechanic Charles Freeman, the two finally discovered that white birch was perfect for their purpose being soft and pliable and retaining a faint sweet odor. As the tree grew in abundance in Maine, Forster set up his operations there, opening his first toothpick mill in an old starch mill in Strong in 1887.

These first toothpicks were flat, but Forster and Freeman soon created a round toothpick that tapered to a point, a design that was so refined it seemed almost elemental in its simplicity. But what was to be done about the folksy Americans who still liked to whittle their own toothpicks out of twigs? How could Forster convince them to forswear their rough handiwork for his machine-made masterpieces?

It was here that Forster revealed the dark side of his genius. To create demand Forster would hire people to ask for toothpicks in stores.

A postcard showing Hotel Strong, c. 1905, with the toothpick mill beyond. (Photo: Public Domain/WikiCommons)

A postcard showing Hotel Strong, c. 1905, with the toothpick mill beyond. (Photo: Public Domain/WikiCommons)

When the shopkeeper was forced to admit he didn’t carry any, the shills left and Forster would appear soon afterwards offering his wares to them. In Boston, he hired Harvard men to dine at the city’s finest restaurants. As Forster himself recalled:

“After dinner, the Harvard student, in a loud voice, was supposed to ask his waiter for a toothpick. If the restaurant didn’t have any, then the young man was supposed to complain loudly, and inform the waiter that he would never again eat in the establishment.”

Soon toothpicks became essential signifiers of status, with cane-twirling dandies chewing on toothpicks outside fashionable hotels to suggest that they had just finished eating therein.

The patent application for a toothpick,1885. The filing reads: “In the drawing I have shown a tooth-pick such as I have described rounded, compressed, and tapering gradually from its center to each end.” (Photo: Google Patents US448647A)

There were a few bumps along the road. An editorial in the New York Times in 1884 decried the habit of women picking their teeth in public, announcing that a lady “cannot feel at ease on rising in the morning unless they consume two or three toothpicks before breakfast.” But few cared. Soon Forster was producing 500 million toothpicks a year and demand was outstripping supply. Competitors sprang up throughout Maine.

Charles Forster’s Toothpick Mill, c. 1900. (Photo: Collections of Strong Historical Society/ Courtesy vintagemaineimages.com)

Charles Forster’s Toothpick Mill, c. 1900. (Photo: Collections of Strong Historical Society/ Courtesy vintagemaineimages.com)

By WWII, American toothpicks were at their most popular, and Strong remained at the center of toothpick production, even emblazoning its fire engines with the words, “Toothpick Capital of the World”. But in the post-war, years nylon floss cut into the market, as did cheap imports from China and Southeast Asia. What’s more, picking one’s teeth at the table became something of a social faux pas, something your rough-and-ready grandfather might do. Even though 8,000 people a year were still being injured by toothpicks, sales plummeted in the 1980s. Strong attempted to diversify with the Forster firm inventing toothpicks with square middles that prevented them rolling off the table, but it was too little too late. Its toothpick mills slowly began to shut down.

The Forster Manufacturing Company’s mill was the last to go, closing in 2003. Strong makes not a single toothpick these days. Like the passenger pigeon that once flew in billion-strong flocks over Maine before being hunted to extinction, so the Strong toothpick, once found in pearly whites the world over, has entirely vanished.

Follow us on Twitter to get the latest on the world's hidden wonders.

Like us on Facebook to get the latest on the world's hidden wonders.

Follow us on Twitter Like us on Facebook