How To Escape A Building By Dropping Through a Fabric Esophagus

A net escape chute at an air traffic control tower in Missouri (Photo: U.S. Air Force)

The opening to an escape chute isn’t exactly inviting. Mostly used on industrial rigs or in buildings when other emergency exits are unsafe, the chute, at its entrance, looks something like the maw of a blood-sucking lamprey (except without the teeth) or, if we’re being honest, sort of like the terminal end of your digestive tract.

To use the chute, which is made of concentric tubes of fabric, you must entrust your body to this orifice.

“If we get a job that’s a reasonable size, we turn up with a scaffold, with an escape chute about five meters high,” says Eric Hooper, the owner of Escape Chute Systems. (Five meters is just about 16 and a half feet, or two short stories high.) “We train people to go through, and if they’re going to too fast we can slow them down. Then we take up them up to the roof. It could be between 40 meters and 80 meters”—between about 130 feet and 260 feet—“high, and there’s a mental thing then. They know they’ve got an 80 meter drop.”

There’s alway someone who balks at going through. He’ll take that person, rush them to the front of the line, and tell them: There’s a fire. You can jump. You can stay up here, be burnt and die. Or you can you use the chute.

They always go down, and they’re always happy about it, under the circumstances. “It’s long, and it’s scary. There’s no other way to put it,” says Hooper. “When you’re going down there’s nothing underneath you.”

In the annal of escape technology, the escape chute never really had its big moment, but the idea, in one form of another, has been around for about two centuries. In 1813, a collection of recently patented inventions described it as a bag “by which a person on the highest stories of houses may expeditiously descend.” It was “composed of a single piece of strong cloth, about twenty-two meters long and two meters wide.” In this model, the tube was then pulled away from the building at an angle. People could get in it and slide down, safely, to the ground. In one experiment in Geneva, a M. Bordier reported, “twenty-two persons have descended by it in one minute and fifty seconds from a fourth story.”

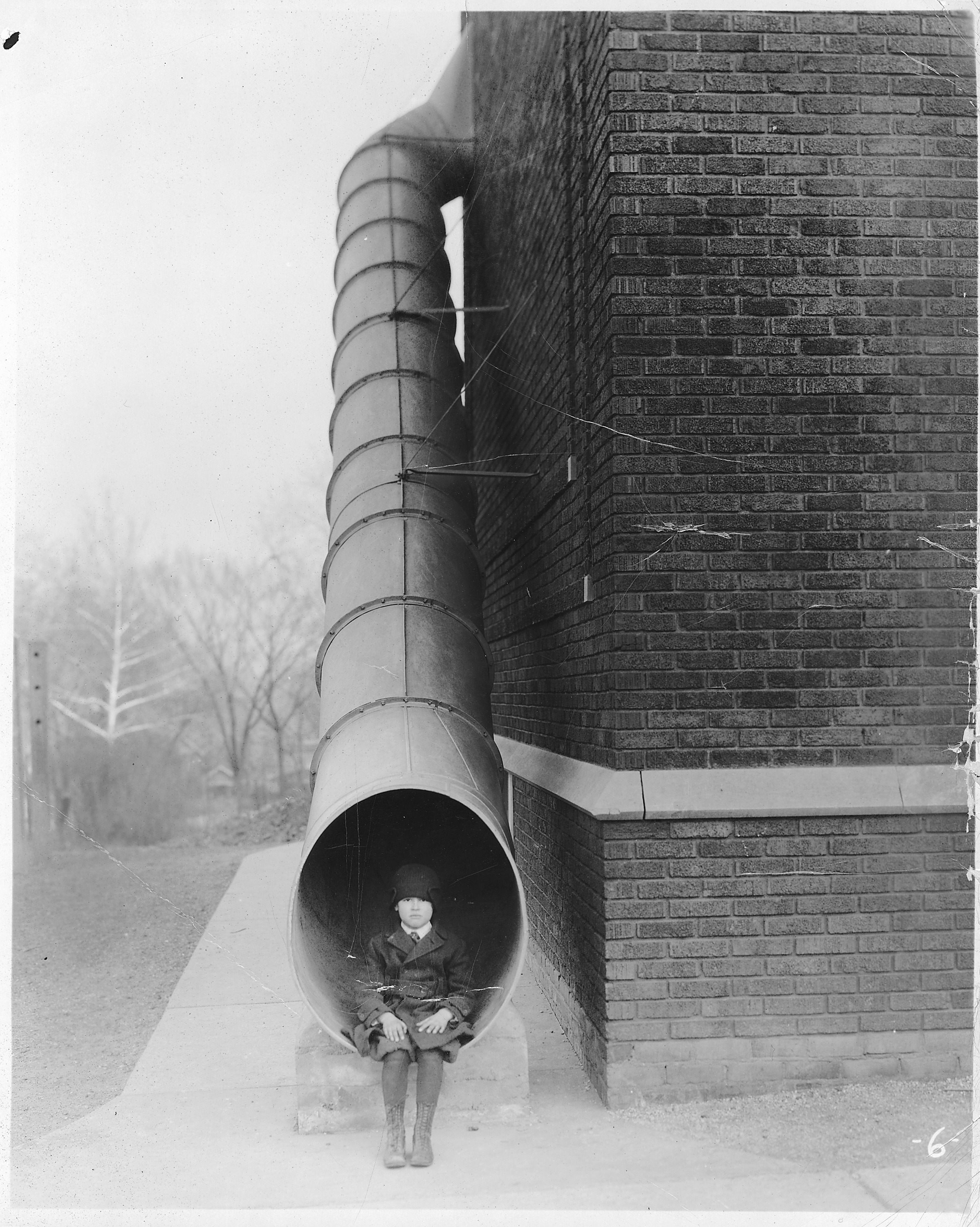

Early in the 20th century, some schools installed metal escape chutes, not unlike slides. In 1948, an Atlanta hospital installed a similar, spiral escape chute through which patients, still in their beds, could be evacuated.

A metal escape chute from the early 20th century (Photo: NARA/Wikimedia)

But the chutes began gaining popularity again around the 1970s, as high-tech fabrics improved their performance. (The exterior layer can now be fireproof, for instance.) There are three main designs: the one Hooper sells, where the tube drops straight down, one that requires the bottom end to be anchored at an angle to the building, and one that involves an interior, spiral-like structure that slows down the person’s descent.

Although some office buildings do install escape chutes, they’re most often used in higher risk industries. Most of Hooper’s sales, for instance, are to mining companies, which need easy routes of escape from huge machines that can rise around 40 feet high. They’re also used on sites like oil rigs and air traffic control towers—places where the expense of the chutes, which can cost more than $10,000, are easy to justify. The technology is also more popular outside the U.S.; Asia is a booming market.

As long as people don’t choke while entering the chute, it is an expeditious point of exit. Once you’re inside the chute, you can move fast: up to about 12 feet a second, according to Hooper, although few people go that fast. A couple dozen people per minute can enter the chute: one company puts it as high as 30. When you’re inside, if you look down, you’ll see the person descending in front of you.

What everyone wants to know, according to Hooper, is what about people who are overweight? And, he says, there is a limit to how big a person can be. There’s a metal ring holding the top of the chute open, and it’s about two feet across. To use the chute, you have to be able to fit through that ring.

But the chute can handle quite large people. When Hooper was installing a chute at the Santa Monica pier, a “massive policeman” wanted to be put through. “I thought, no, I can’t put him through, but he insisted,” Hooper says. They took the ring off the top of the chute, and the policeman’s body fit through that. “We put him through,” says Hooper. “If they stretch up like that”—he raises his arms alongside his ears, stretching the body into a straighter line—“they can do it.”

Inside the net (Photo: U.S. Air Force)

Follow us on Twitter to get the latest on the world's hidden wonders.

Like us on Facebook to get the latest on the world's hidden wonders.

Follow us on Twitter Like us on Facebook