See the Pixelated Desert That Powers Your Phone Battery

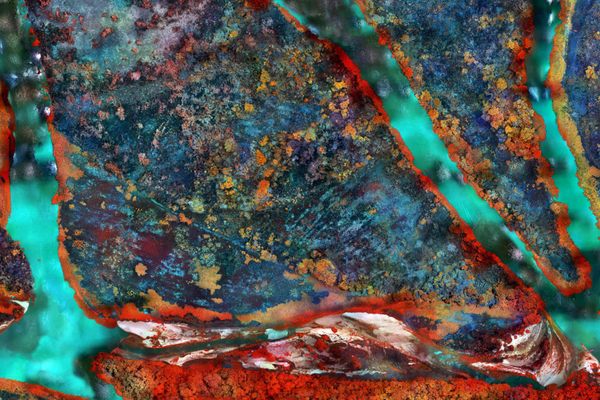

A lithium lakebed in Chile from above.

Just under the surface of the Salar de Atacama in Chile is the world’s largest and purest active reserve of lithium. Surrounded by volcanoes, the salar, or dry lake salt flat, is the “literally the driest place in the world,” says United States Geological Survey (USGS) mineral commodity specialist Brian Jaskula. Andean flamingos touch down periodically as they migrate between their breeding grounds in Chile and Argentine wetlands, but there is no full-time life visible there—not even insects. That aridity makes it the hottest spot for lithium extraction in the world.

From above, as in this photo recently released from NASA and the USGS’s Landsat-8 satellite, it looks like a mosaic of rectangular oases. Swimming-pool blues and hot whites, and greens that range from dark and lawn-like to Mountain Dew–hued pattern a flat umber backdrop, representing different stages in the 18-month lithium-mining process. The blues are brine freshly drawn from as few as 15 feet below the salar floor, containing 0.02 percent lithium, a concentration that seems small but is about 100 times higher than commercial lithium sites elsewhere in the world.

Until 2003, lithium was a relatively minor commodity, used to stabilize fluctuating moods and temperatures—in pill or solution form and in glassware such as Pyrex—and as a hydroxide to grease car door hinges and wheels through hot days and frigid winters. Now, lithium greases the wheels of modern life, in the form of lithium-ion batteries that power smartphones, laptops, and, increasingly, electric vehicles.

“Rain is the enemy of a brine operation like this,” says Jaskula. With a high initial lithium concentration below and a lot of sun and hot wind to do the drying work once its above ground, the Salar de Atacama contains the perfect characteristics for lithium extraction. The goal is to evaporate water and remove adulterating elements such as magnesium, boron, and salt from the brine until it reaches a lithium concentration of six percent—in the chartreuse pools—at which point it can be trucked away to processing plants where it is separated and shipped all around the world.

While electric vehicles promise to improve upon the environmental degradation caused by fossil fuels, the appetite for lithium might not be so sustainable either. The International Energy Agency predicts that more than 120 million new electric cars will be on the road over the next 20 years, requiring a significant quantity of lithium. Just yesterday, a new lithium-mining prospector in the region dropped its project due to protests from the Atacama indigenous community, and it was quickly swallowed up by Chilean SQM–one of two companies that dominate the lithium business in Chile (the other is American Albermarle). While lithium looks like a climate change oasis from above, its future is still not so clear.

Follow us on Twitter to get the latest on the world's hidden wonders.

Like us on Facebook to get the latest on the world's hidden wonders.

Follow us on Twitter Like us on Facebook