Inside NASA’s Contest to Develop the Space Food of the Future

The race to provide astronauts with fresh bread and 3-D printed steaks can also help food scarcity on Earth.

Tucked in a quiet industrial park in suburban Ohio, an office building holds some of humanity’s future food solutions. In the lobby, glass panels line a wall, each highlighting a significant achievement in food-production history, from the advent of deep-frying to the invention of canning to the development of pasteurization. This timeline is a good introduction for what lies farther inside: a company that’s creating 3-D printed foods.

When I visited in August 2022, that company—BeeHex—was just one of the 18 teams selected to compete in the Phase II of the Deep Space Food Challenge, a contest sponsored by NASA and the Canadian Space Agency. The teams’ task: Create foods that will not only feed a crew of astronauts on a deep-space mission to Mars for at least three years but also improve life on Earth.

Innovators from around the globe signed on to design food-production technologies that could potentially earn cash prizes and even enter orbit. When the contest began in 2021, there were 239 teams from 29 countries vying for the opportunity to have their food tech included on a future space mission. And just last month, NASA whittled that figure down even further, to eight winners of Phase II. But before we skip ahead to the winners, it’s important to meet some of these teams and understand why such a contest exists in the first place.

With the successful launch of Artemis I (NASA’s first phase to get astronauts back to the moon, and then Mars) and recent announcement of Artemis II (a crewed lunar flyby test scheduled for 2024), NASA is one step closer to getting a crew to Mars. These expansions into space exploration come with questions about how to feed astronauts around 127.31 million miles away from Earth. Future foods should produce minimal waste, require minimal resources, and be actually tasty—something lacking in current and past space food.

In the 1960s, astronauts such as John Glenn squeezed out meat and applesauce from tubes while sucking their meals through straws and dining on freeze-dried foods. Powdered drinks and freeze-dried foods were also used on Gemini’s Earth-orbit missions. To spice up their bland diets, some astronauts took extreme measures: NASA pilot John Young made history in 1965 when he smuggled an unapproved corned beef sandwich aboard Gemini III.

Space food improved slightly for Neil Armstrong and Buzz Aldrin, the first humans to set foot on the moon in 1969. As dehydrated foods replaced tube foods, Apollo astronauts were able to add water to dried beef and eat it with a spoon. Their meals were edible, but still a poor imitation of those available on Earth.

The 1980s brought about the Tang craze, when civilians bought the orange-powder drink to eat straight from the jar or mixed with water. Contrary to popular belief, NASA did not invent Tang, and astronauts did not love it. In 2013, Buzz Aldrin did not hold back when he told NPR, “Tang sucks.”

In the decades since, menu options, nutrition, and flavor options have improved (astronauts even get to taste-test meals ahead of time), but space food still has lots of room for improvement. To be fair, the food—all of which gets processed at the Johnson Space Center in Houston, Texas—must meet strict criteria for space. Food that produces crumbs, for example, could pose a danger to a shuttle’s system. Loose Cheerios or a cup of coffee could spell disaster in a zero-gravity environment. Bread is nonexistent in space, making a juicy burger served on a bun (or a corned beef sandwich) out of the question. Instead, astronauts rely on soft tortillas for sandwiches.

More work still needs to be done to be Mars ready. The challenge of creating sustainable and palatable food in a limited environment is one that NASA’s contest aims to address.

“We really looked at everything,” says James Hury III, director at the Translational Research Institute for Space Health and the lead judge for Phase II of the competition. “Crickets and insects, and things that may not sound appetizing, but you’re encouraging people to come up with ways to make them an appetizing source of protein.”

Over the course of this competition, I spent 18 months interviewing several teams in the United States and across the globe. They took time to share their knowledge and their dreams for a better future—and sometimes even the inner-workings of their labs or, in one case, their garage. Though each team differed in their approach—plant growth, manufactured foods, bio-culture, and more—they all had a common goal of making a positive difference on Earth and in space. The possibility of astronauts savoring a slice of good pizza or a real sandwich seemed light-years away—until now.

In 1962, The Jetsons debuted. In the cartoon, George Jetson flew a space car and his son, Elroy, could make his own dinner with a press of a few buttons—peanut butter, sardines, liverwurst, baloney, sardines—and, blastoff, a full hoagie shot into little Elroy’s hands.

Today, reality has caught up with science fiction: At BeeHex, a company in Gahanna, Ohio, a similar version of The Jetsons’ sandwich scene is taking place with 3-D printed foods.

Here, Anjan Contractor is creating 3-D printed foods for the Deep Space Food Challenge. Contractor and his team have designed what they’ve dubbed a Universal Food Fabricator (UFF) for missions to Mars. The machine uses a dehydration chamber where vegetables, fruits, and meats are changed to powder form. Then, the foods get stored in air-tight cartridges where they can be kept for years—a necessity for the long mission to Mars.

The UFF system, Contractor says, starts simply enough: It’s based on the same system of dehydrating foods and packaging them in a vacuum seal that NASA has been using since the 1970s. But BeeHex is adding a few tweaks.

“What if besides creating a long shelf life, we could improve the food’s texture using a 3-D printing food system?” Contractor asks.

It’s August 2022 and I’m sitting across from Contractor in BeeHex’s conference room. To illustrate how the process works, he holds up a clear capsule that looks similar to the tubes that come through a bank drive-through window. These cartridges hold powdered food ingredients that are the “printing material” that will create foods like pizza or steak. When the capsule is inserted in the machine, water is added and an extrusion process creates a palatable texture. Contractor says he’s able to create a juicy, meaty-tasting steak with a rich aroma that has the same appearance of steak served at any fine restaurant.

“If we can create foods that are exciting, with texture, taste, and smell, we can change the future of [space food],” Contractor says. “You could choose a 3-D printed steak and broccoli. Or pizza.”

Contractor leads me into a large lab where the atmosphere is buzzing with activity. One group of employees huddle around a screen looking over data, while another group troubleshoots a laser problem, and a few congregate near a kitchen counter lined with pizzas for a quick bite.

Using natural food ingredients, Contractor intends for his 3-D printed food device to be useful for the consumer market as well as outer space. To test the concept, he created a 3-D printed pizza and partnered with Donatos Pizza, a regional chain headquartered in Ohio. BeeHex even shares space with Donatos so they can better collaborate. While there, we walked past a mound of pepperoni about a foot high—part of thickness trials to create the perfect pepperoni slice.

“Pizza was a natural fit to begin with because it’s layer by layer—crust, then sauce, then cheese, and toppings—just like 3-D printing,” says Contractor. “But the market for a 3-D printed pizza is not there.”

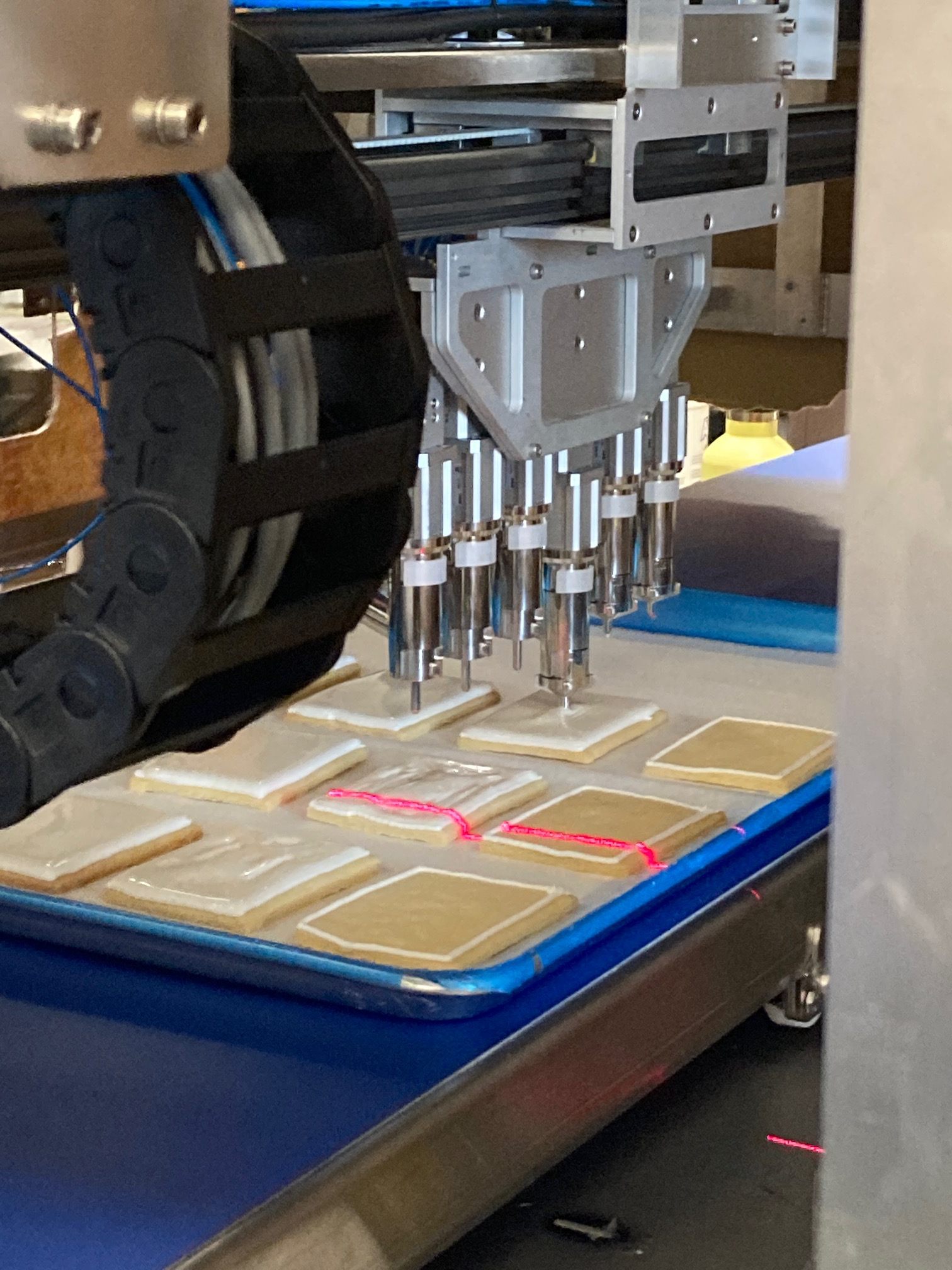

Making pizza is not labor intensive, so producing 3-D printed pizzas didn’t solve any labor issues. Cake decorating, however, is labor intensive, so BeeHex invented a 3-D Cake Writer that frosts and personalizes cakes. Contractor sells these devices to big-box stores for automated cake decorating to finance his deep space food project. But the dessert decorating doesn’t stop there: Contractor tests his 3-D printer prototype for NASA’s contest with the task of frosting cookies. Toward the back of the lab, the printer’s red laser beam scans across a sheet. After the sensor identifies each cookie’s location, a metal, robotic tube pipes white frosting in lines.

Space-funding skeptics often question if putting money into space exploration makes sense when there are pressing problems here on Earth. To that, Contractor argues that the two are not mutually exclusive. “Space food inventions have and will continue to improve life here on Earth.”

Contractor smiles and talks animatedly when discussing how his 3-D food printer will bring delicious foods with long shelf lives for astronauts. But his dark brown eyes turn serious as he speaks of solving big problems like food waste and food shortages. He believes this technology could be applied to refugee camps, Arctic laboratories, and disaster relief locations before they’re launched into orbit.

Later, he hopes for innovations like his printer to become mainstream to address more widespread issues, like food chain supply problems.

“The years when we have overproduction, the waste that we are creating can be saved for later,” Contractor says. “Even the edible parts of plants that we discard like the leaves, the roots—these can be dehydrated and stored for the long term. We can mix these foods with other 3-D printed foods, and make them palatable.”

To ensure this palatability, Contractor has hired an in-house chef. Just before I leave BeeHex, Contractor and the chef chat about the final details for a 3-D printed fish piccata. They’ve decided to use her classic chicken piccata recipe, but swap the chicken for cod. Their conversation is accompanied by the hum of the red laser scanning across sugar cookies.

Before leaving, I take one final look at the food innovation timeline in the lobby. My eye travels back to the glass panel that reads “Canning in 1795.” A quick internet search reveals that the invention of canning was the result of a French contest created to solve a problem. Napoleon offered a reward of 12,000 francs for the invention of a new food preservation method. Nicolas Appert won Napoleon’s award, changing food production forever. Now a new challenge looms: What obscure food idea of today will help our food landscape and be commonplace years from now?

Like many people stuck at home during COVID-19 lockdowns, Hope Hersh did a lot of baking. But this wasn’t just experiments in sourdough starters; Hersh was developing nutrient-packed bread for outer space.

“I was testing at low temps in my oven for long periods of time. All was going well until my oven broke,” she laughs.

Hersh, the leader of team Space Bread, is a PhD student in plant molecular and cellular biology at the University of Florida in Gainesville. When we speak over Zoom in August 2022, a big smile spreads across her face as she tells me about her longtime dreams of working for NASA. When she learned that the Deep Space Food Challenge would blend her passions for baking, plant science, and space, she jumped at the opportunity.

Safely making bread in space has been previously off limits since crumbs can disrupt sensitive equipment. Bread also lacks essential nutrients and is too large to store on a spacecraft. To address the crumb and nutrient issues, Hersh tinkered with a no-knead recipe known to produce little to no crumbs. She landed on a ciabatta-type bread that uses flour, yeast, and salt, along with edible algae for nutrients. To minimize space, all the ingredients can be stored in a reusable, food-safe plastic bag.

“The idea for the plastic bag came about when my [doctoral] advisor was getting his blood drawn,” Hersh says. “The idea is brilliant because the FEP [Fluorinated Ethylene Propylene] bags can tolerate high and low temperatures, ideal for space.” This means the bread can also be baked inside the bags: Hersh explains that gas flows between the plastic membranes, preserving the cells inside and creating an ideal environment for yeast to rise.

The result is a soft, chewy bread that doesn’t crumble. Hersh also notes that the algae doesn’t impart a swampy aroma or flavor: It looks, tastes, and smells just like home-baked bread, she says.

With its compact size and perfect portability, Hersh notes that Space Bread would also be ideal for disaster relief missions and in military meals. Not only that, but fresh-baked bread would offer something invaluable to anyone far from home, be it a soldier, refugee, or astronaut: warmth and comfort.

“I can’t imagine being gone for five years on Mars and never being able to smell fresh-baked bread,” Hersh says. “Bread is a reminder of home.”

Hersh isn’t alone in her belief in the power of bread. Nearly 1,800 miles from her university lab, another innovator is making great strides in the field of space baking.

On a sunny morning in Boulder, Colorado, several windows shine light into Jim Sears’s garage. “This is my lab,” he says as he walks me through a virtual tour during a Facetime call. “My wife is highly annoyed that we can never park our cars here.”

The garage is tidy with a wooden desk on one side and a section set up with a lathe and milling machines. Another area has a table lined with foods such as a giant box of Rice Krispies cereal, Bisquick baking mix, and pouches of dried potato flakes. Finally, he leads me to an unassuming machine that’s just slightly bigger than a toaster.

“This is where I get to geek-out,” he laughs. This is SATED, a space oven that could be the first oven to safely cook foods in zero gravity.

When I talked with Sears in March, SATED—an acronym for Safe Appliance Tidy Efficient Delicious—had been declared one the Deep Space Food Challenge’s Phase II Finalists, the stage of the competition when NASA judges visit teams on-site and conduct taste tests.

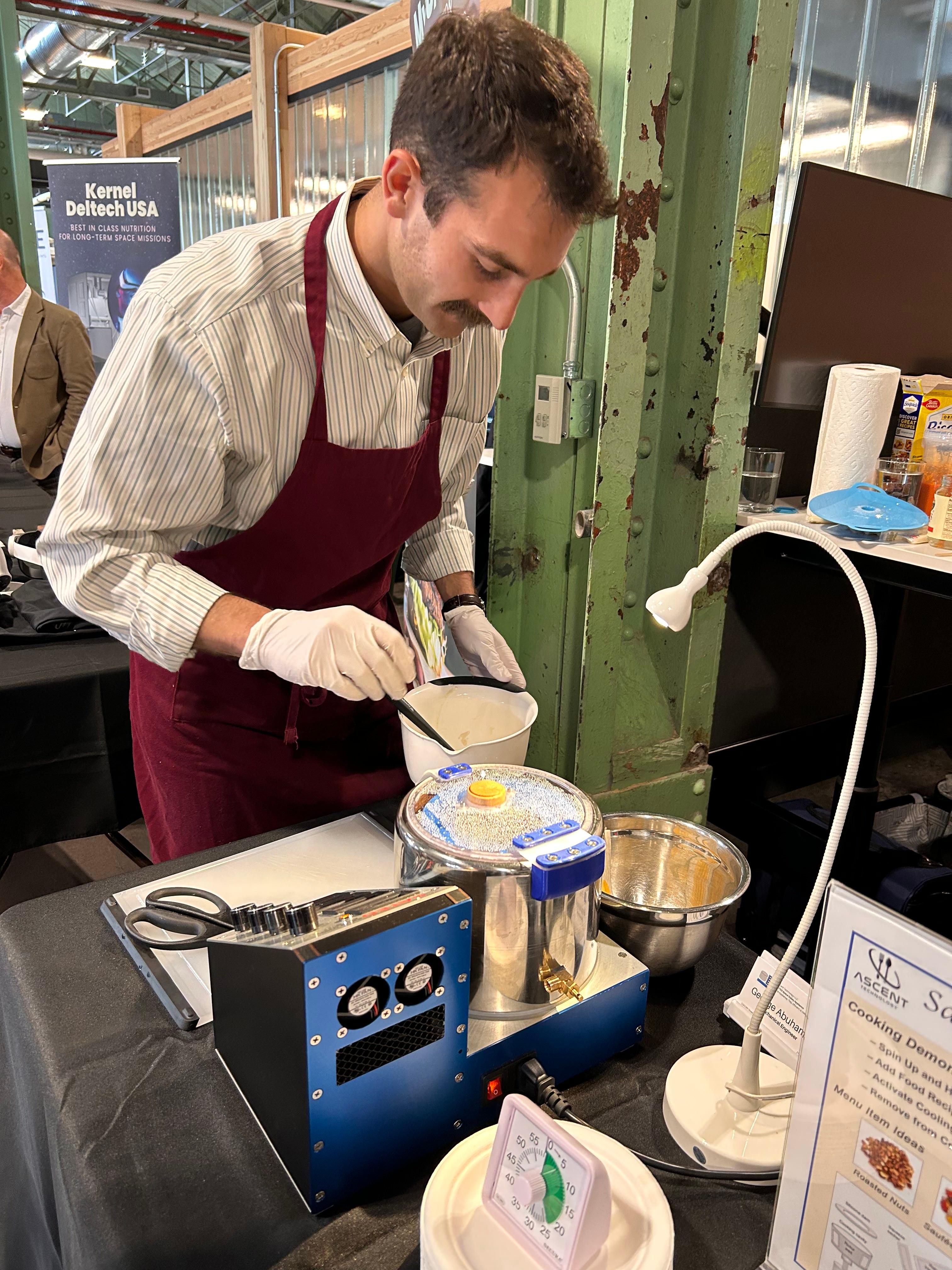

Sears says his small oven is ready for Mars and can brown foods like peach cobbler and pizza to perfection. Inside, food ingredients spin within a cylinder that uses centrifugal force to press them directly against a heated inner wall. With SATED, astronauts would be able to build their own meal by injecting ingredients into a central hole in the end of the cylinder. They can then add a variety of ingredients one at a time while varying the cooking temperature and time accordingly. Ingredients like baking mix, water, dried fruits, cheese, pepperoni, and many others can be sequentially suctioned into the cooking cylinder and baked. And, like magic (well, physics), a cylinder-shaped version of, say, peach cobbler is made in about 12 minutes.

Before Sears’s oven, many safety considerations have stood in the way of cooking in space. Trying to cook in a weightless environment, for one. And the risk of fire and smoke would be catastrophic to a space mission. SATED uses ceramic heating elements, not unlike those used in household ceramic space heaters, that automatically shut down before they ever approach the temperatures that could cause smoke or fire.

After spending years as a hardware systems engineer for a major aerospace company, Sears left to focus on his own entrepreneurial projects and inventions. In 2022, he founded his own company, Ascent Technology, specifically for the challenge.

“SATED is, by far, the most technically exciting and I believe, ultimately the most meaningful project I’ve ever worked on,” Sears says.

When the NASA judges made an on-site visit to test SATED in Sears’s garage, they witnessed how the fire- and smoke-free oven could cleanly bake, fry, and simmer ingredients ranging from dried fruits to dried cheese crisps to fresh vegetables.

“They ended up doing most of the cooking,” Sears says. “There was a thrill of discovery.” The judges made dishes including cranberry cobbler, shepherd’s pie, and pizza. The fan favorite was an omelet made from dried egg crystals, bell peppers, and cheese crisps.

Operating the oven is simple: Sears made using SATED as easy as using a microwave. The newest model has just four digital readouts: one for cooking temperature, one for setting artificial gravity, one to activate a fan that sucks dried foods into the cooking rotor, and one for measuring the mass of ingredients in grams.

Sears envisions his oven not only in outer space but for safely cooking in tents, submarines, and other areas where a closed environment and water usage are an issue. But when it comes to space, he sees an advanced, yet easy-to-use kitchen as a crucial aspect of long-distance travel and even potential colonization.

“The ability to cook, serve, and gather around good meals is a necessity of human life that will become essential for sustainably colonizing space,” he says. “Being able to eat a genuine crispy, cheesy, tomatoey piece of pizza on the surface of the moon, or on the way to Mars, means you could actually be inspired to be there.”

In a video about NASA’s Deep Space Food Challenge, retired astronaut Scott Kelly reflects on his time growing red lettuce and orange zinnia flowers in space. “Growing, preparing, and eating good food makes you feel connected to home,” he says. “The food on the ISS was sufficient, but there’s always room to grow.”

The Deep Space Food Challenge has a few teams trying to crack the code of farming in microgravity. The Auto Terra Project (formerly known as Arrakis Terrarium) is one such team. When we speak in September 2022, the crew of UMass-Lowell undergrads is hard at work perfecting a third prototype for the contest.

“Essentially, it’s a community garden inside a terrarium enclosure,” team leader Ariel Shramko says. “Inside this terrarium, we can control temperature, humidity, hours of daylight. We’re creating an ideal environment.”

Shramko, an environmental engineering major, says her love of plants and the environment came long before college or contests.

“Creating ecosystems has been a childhood dream of mine,” she says. While other kids were playing hide-and-seek, she was making mini terrariums out of peanut butter jars. “I was a bit of a nerd.”

So far, Shramko and the Auto Terra team have grown tomatoes, celery, spinach, green beans, mushrooms, and potatoes in their enclosures. By making the system almost entirely automatic—with the terrarium self-regulating its humidity, air temperature, hours of daylight, and more—it would free astronauts to focus on other tasks besides the minutiae of farming.

But it’s not just about Mars. Their goal, Shramko says, is as much about space travel as it is about making fresh vegetables accessible for more people on Earth. By keeping the external environment separate from the internal environment, crops can be grown anywhere—from spacecraft to city apartments. The team has already built one version of the terrarium specifically for use in urban food deserts.

The team’s recent prototype design emphasizes this accessibility. “Our goal is to have all the fixtures of the unit available using 3-D printing,” team member Eliot Pirone adds.* In the background on our Zoom call, Pirone’s 3-D printer is spitting out a part for the terrarium from his home office. “We want to make this accessible to as many people as possible,” Pirone says. What can’t be printed can be purchased from a home improvement store.

The result is a printable prototype that is not only compact and portable, but cost-effective and easily replicated for use in lower-income communities. The terrarium’s exterior, for instance, is soft-sided like a canvas and has vertical supports that can be folded flat for easy portability. It’s a big improvement from their original. “Our first one was enormous, and we found out it was a total pain to move,” Pirone laughs. “We needed to have a unit that could fit through a doorway.”

“We’re university students,” Shramko agrees, chuckling. “We don’t have big cars.”

No matter the outcome of the Deep Space Challenge, Shramko notes that the ultimate goal is bringing their terrarium to communities coping with food scarcity.

“While the Mars stuff is cool and all, a huge part of our mission is about getting this to people who actually need it.”

Meanwhile, in an entirely different hemisphere, another team at another university is also looking toward the power of plants.

In Piracicaba, Brazil, Paulo Hercílio Viegas Rodrigues is looking at the Amazon rainforest to provide growth solutions for Mars. When we chat over a Zoom in October 2022, Rodrigues’s enthusiasm pours out through animated hands as he describes the botanical bounty of the region.

“The rich diversity of plants in the Amazon rainforest is a living laboratory for healthy foods found nowhere else,” he says.

One such food is taioba, a tropical plant native to Brazil and parts of Africa. Also known as arrowleaf or elephant ear, the plant’s leaves supply vitamin A, vitamin C, and phosphorus and have a taste akin to spinach.

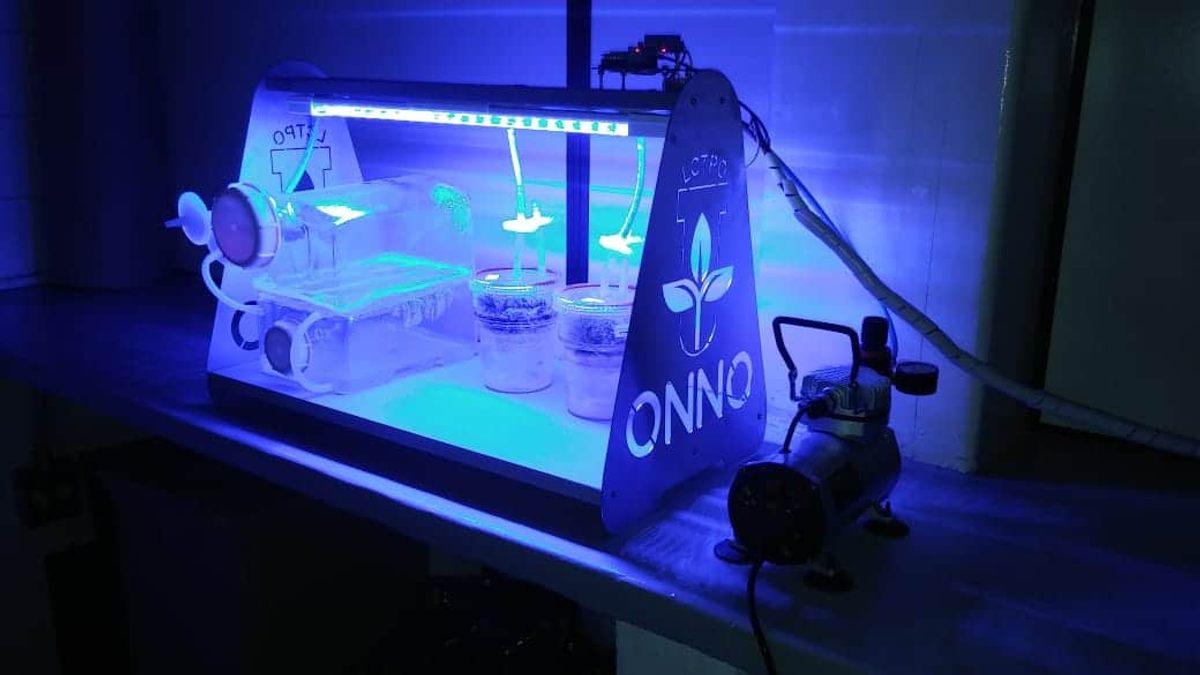

Rodrigues’s team of agronomists and computer engineers from the University of São Paulo goes by LCTPO, short for the Laboratório de Cultura de Tecidos e Plantas Ornamentais (“Laboratory of Ornamental Plants for Tissue Culture”). Together, they’ve produced a unique farming system that can grow taioba plants that are small and lightweight but also highly concentrated with nutrients.

Since taioba plants typically produce large leaves, Rodrigues and his team use artificial blue light to reduce their metabolism, allowing the crops to grow slowly and limiting their size. “Our laboratory is like a space station,” he laughs, reflecting on how he must shut out Brazil’s bright sunshine and create a dark environment that glows with a soft, light blue.

Since the plants are smaller, however, Rodrigues and his team wanted to ensure they had a high concentration of nutrients. To achieve this, he adds terpenes, compounds known to particularly increase carotenoids. The result is nutrient-packed crops that grow in minimal light, require minimal space, and can be continually produced for three years—perfect for the long journey to Mars. Their space farm also features a space-conscious vertical garden and a tissue culture laboratory to maintain a seed bank.

Like the other teams, Rodrigues sees potential for improving foodways on Earth as well as outer space. If he can figure out a way to make a cost-effective version of the tech, he says, it could be applied to a vast array of different crops in different environments, “providing fresh and high-quality food anywhere on Earth,” from the cold climate of Canada to Middle Eastern deserts.

Rodrigues’s expertise may be plants on terra firma, but he’s had a lifelong fascination with outer space. During our conversation, he shows me a piece of paper. “This is from NASA,” he says, beaming. “I wrote to them when I was ten years old. They mailed this to me.” He’s holding NASA’s official reply with Neil Armstrong’s “one giant leap for mankind” declaration emblazoned on it. “And now I’m 58. I’ve saved it all these years.”

On Friday, May 19, the remaining teams waited anxiously for the big announcement that would announce the winners of Phase II of the challenge. Many teams flew into New York City to hear the results announced at the Brooklyn Navy Yard. Others listened to the livestream.

Finally just after noon, NASA declared five American and three international teams the winners that would move ahead to the third and final phase of the competition. While BeeHex, Auto Terra, Space Bread, and LCTPO did not advance, Jim Sears’s SATED did.

“You don’t allow yourself to believe you can win until it actually happens,” Sears says. Sears attended the live event, bringing his invention from Colorado to New York, where he provided samples of fresh-baked space pizza straight from his oven.

Other winners included Florida’s Interstellar Lab, whose closed-loop mini eco-habitat produces microgreens, mushrooms, and insects; Sweden’s Mycorena, which created a system that combines microalgae with fungi to produce protein that “feels and tastes like meat”; and Air Company, a Brooklyn-based team that combines human’s exhaled carbon dioxide with hydrogen gas to produce yeast.

Angie Lee—a Phase II judge who worked for NASA conducting human metabolic research experiments with astronauts before becoming a professional chef—says she found projects like SATED particularly promising.

“The proposals I found most exciting are those that give astronauts the ability to cook in space,” Lee says. “Instead of food packets, they allow astronauts to prepare and cook a meal. This builds morale.”

The winning teams now advance to the third phase of the challenge, which will focus on testing each project’s ability to repeatedly and reliably produce food.

The U.S. teams that advanced to Phase III were awarded $150,000 each. Sears intends to use his financial award for further developing his oven. His plans include adapting technologies to be used in orbit and creating a better way to make space ice cream. “I’ve got cooking down,” he says. “Ice cream is next.”

But big dreams take big funds. Sears hopes to secure more money to experiment with parabolic aircraft flights, which reproduce zero-gravity—a highly expensive endeavor. For now, Sears is taking a moment to relax and celebrate his big win with a peaceful camping trip near his Colorado home. “Then, it’s back to work” and, with time, “onto Mars.”

* As of the publication date, Pirone was no longer on the Auto Terra team.

Gastro Obscura covers the world’s most wondrous food and drink.

Sign up for our regular newsletter.

Follow us on Twitter to get the latest on the world's hidden wonders.

Like us on Facebook to get the latest on the world's hidden wonders.

Follow us on Twitter Like us on Facebook